Introduction to Hardness Testing Methods for Tungsten Carbides

Introduction to Hardness Testing Methods for Tungsten Carbides

1、 Tungsten carbide hardness testing method

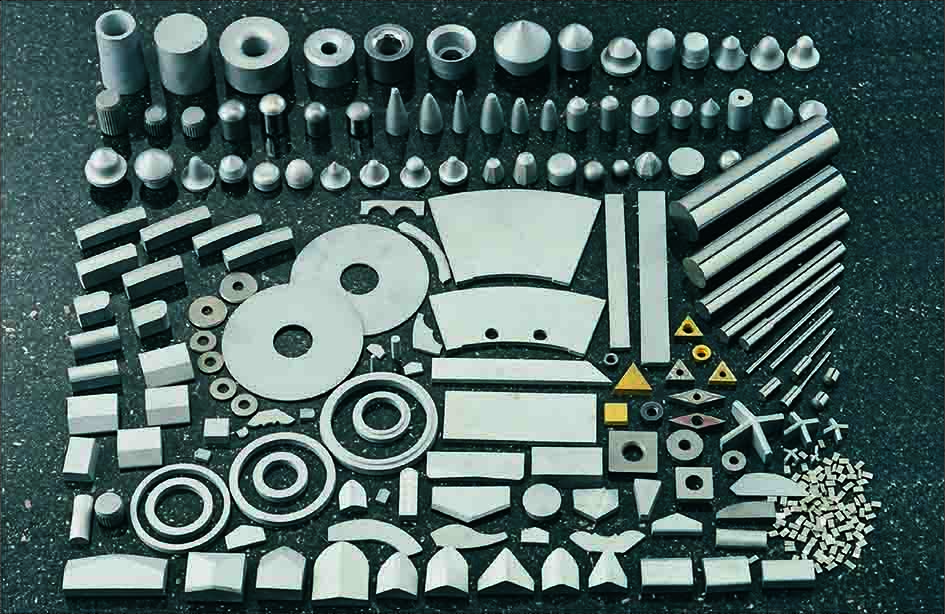

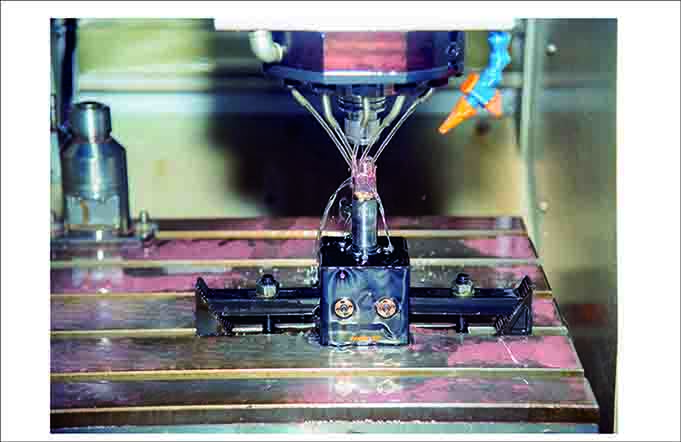

Tungsten carbide is a material with high hardness, strength, wear resistance, and corrosion resistance, commonly used in the manufacture of high-precision parts such as cutting tools, drills, grinding wheels, bearings, etc. Due to the extremely high hardness of tungsten carbides, specialized testing methods are required for hardness testing. Below are several commonly used hardness testing methods for tungsten carbides:

- Rockwell hardness testing method: This is a commonly used method for measuring the hardness of tungsten carbides. It uses a metal hammer head to apply a certain force to the surface of the sample, and determines the hardness value based on the size of its trace.

- Brinell hardness testing method: This testing method is also commonly used, which uses a steel ball or diamond cone to apply pressure to the surface of the sample under a certain load, and then measures the size of the trace to determine the hardness value.

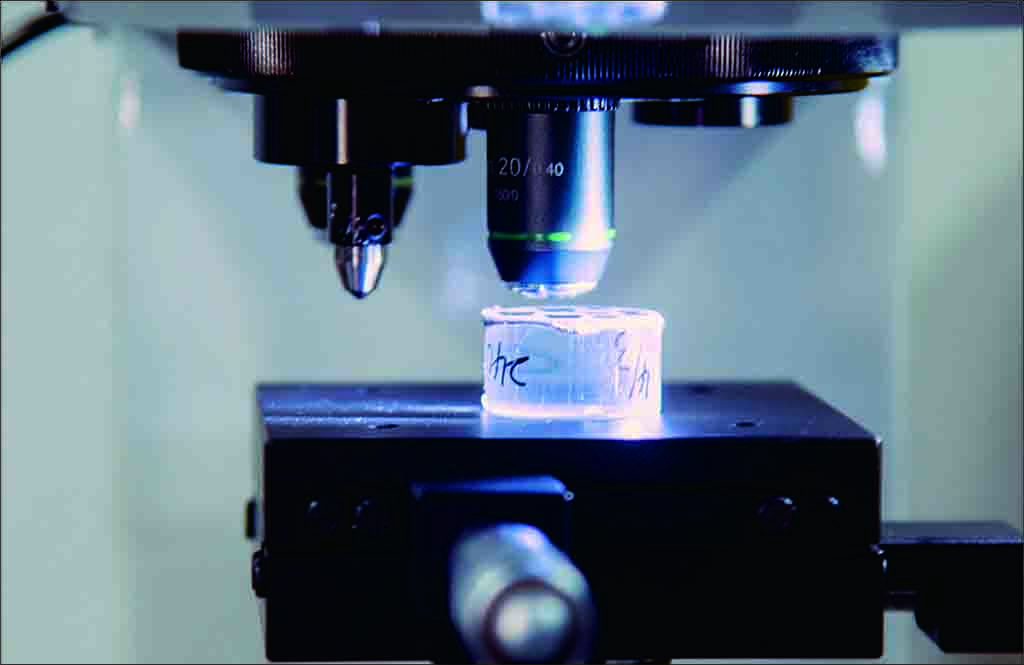

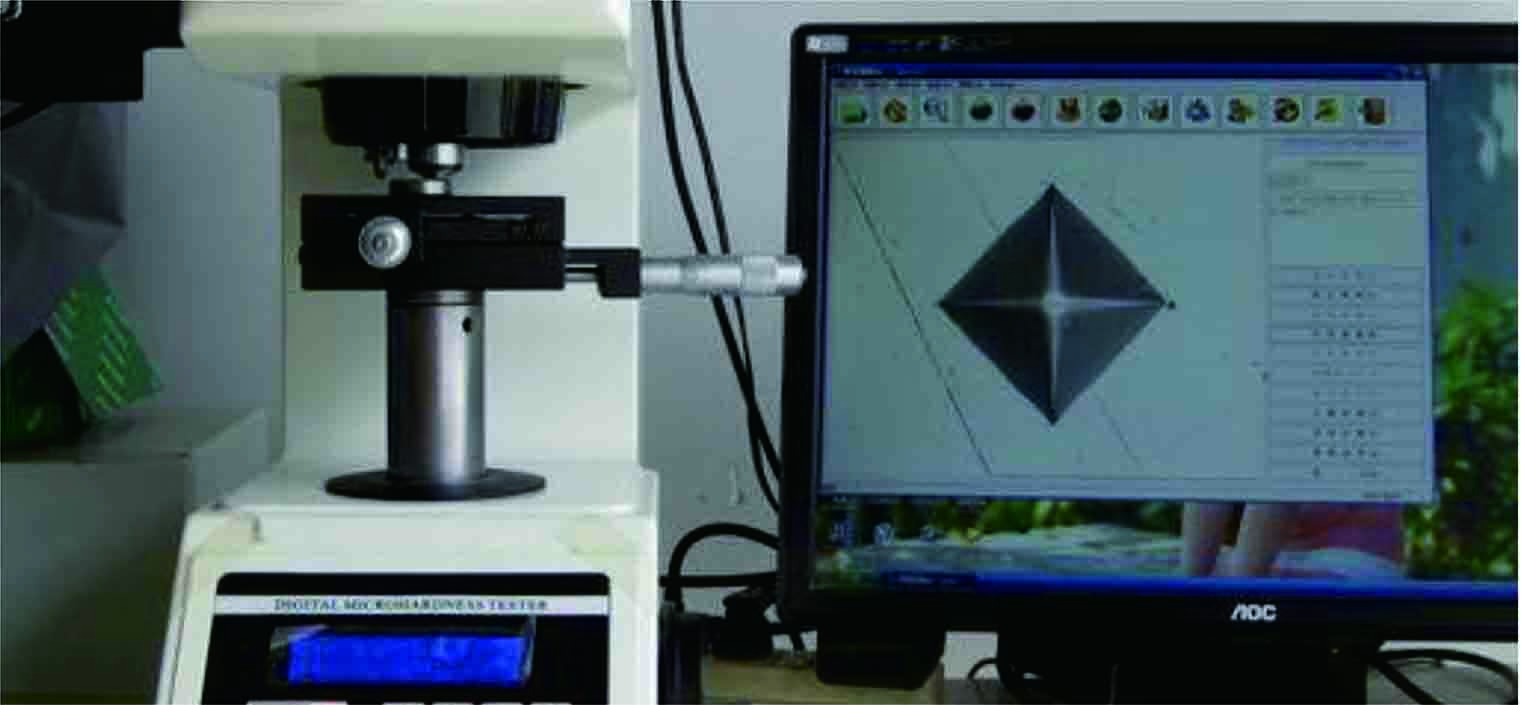

- Vickers hardness testing method: This testing method is mainly used to measure the hardness of thin plates, sheets, and other relatively thin materials. The testing method uses a diamond drill bit to apply a certain load to the surface of the sample, and then measures the hardness value based on the size and shape of the residual imprint.

2、 Precautions and operating procedures for hardness testing of tungsten carbides.

When conducting hardness testing, it is necessary to use corresponding professional testing equipment according to different testing methods, and conduct the test only after the testing instrument is stable.

Before conducting testing, it is necessary to calibrate and debug the testing instruments to ensure the accuracy and reliability of the test results.

When conducting hardness testing, it is necessary to provide sufficient flatness and smoothness on the surface of the specimen, and avoid excessive wear and scratches on the surface of the specimen.

- During testing, it is necessary to accurately control the magnitude and duration of the applied load, and pay attention to preventing excessive load and prolonged load from causing deformation and damage to the specimen.

During the testing process, appropriate protective measures need to be taken to ensure the safety of the testing personnel, such as wearing protective goggles and gloves.

3、 Conclusion

Tungsten carbide is a very important material with wide applications in manufacturing high-precision parts and tools. When conducting hardness testing, appropriate methods must be selected and relevant testing specifications and precautions must be followed to ensure the accuracy and reliability of the test results.