0102030405

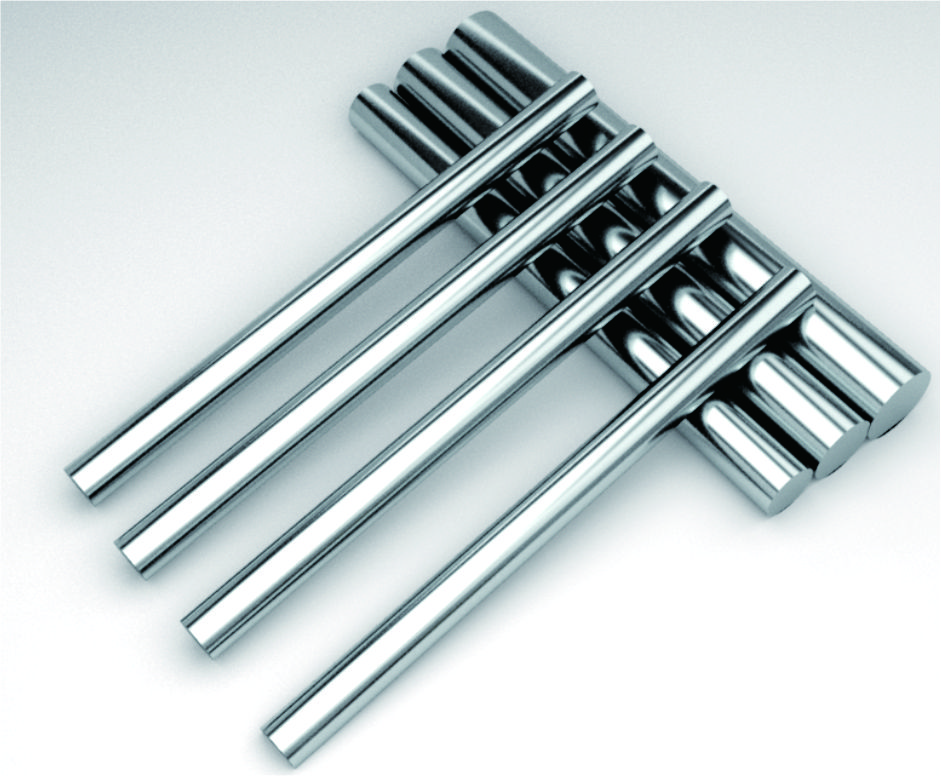

Metric-Cut-To-Length Rod For End Mills

product description

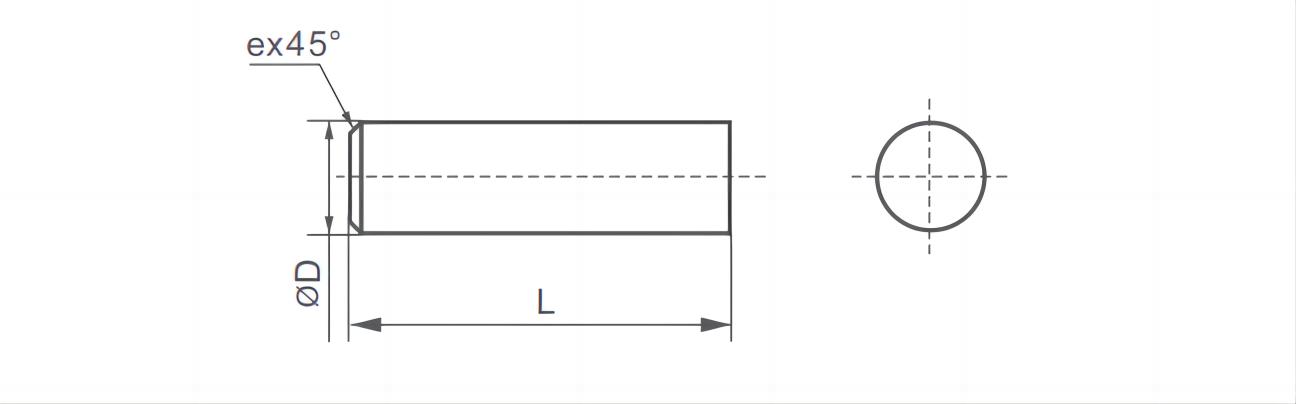

Chamfered cut-to-length ground Cemented carbide rods for end mill and solid twist drill bit

specification

| ΦD | Length | Chamfer | Angle | |

| (mm) | Sintered (0~+1) | (+/-0.1) | (+/-3。) | |

| 3.0 | 40,50,70,100,150 | 0.4 | 45。 | |

| 4.0 | 40,50,70,100,150 | 0.4 | 45。 | |

| 5.0 | 50,55,60,70,80,100,150 | 0.5 | 45。 | |

| 6.0 | 50,60,75,100,150 | 0.5 | 45。 | |

| 7.0 | 55,60 | 0.6 | 45。 | |

| 8.0 | 60,75,80,90,100,150 | 0.6 | 45。 | |

| 10.0 | 70,75,90,100,125,150 | 0.6 | 45。 | |

| 11.0 | 110 | 0.8 | 45。 | |

| 12.0 | 75,90,100,120,150 | 0.8 | 45。 | |

| 14.0 | 75,100,110,125,150 | 0.8 | 45。 | |

| 16.0 | 100,125,150 | 0.8 | 45。 | |

| 18.0 | 100,150 | 0.8 | 45。 | |

| 20.0 | 100,120 | 1.0 | 45。 | |

| 25.0 | 100,150 | 1.0 | 45。 | |

Material Property

| Carbide Grade\Property\Application | |||||

| GB Grade | I S O Grade | HRA≥ | (g/cm³)≥ | (N/mm2)≥ | Application |

|

YG6X-H |

K05 |

93.2 |

14.88 |

3100 |

Suitable for precision machining and semi precision machining of cast iron and metal, it is an excellent material for making integral cemented carbide hole machining tools. Also suitable for woodworking router bit. |

| FD10 | k20-k30 | 91.2 | 14.38 | 3000 | Fine grain, suitable for various milling cutters and hole processing tools. |

|

FK30 |

K20-K30 |

91.6 |

14.45 |

3500 |

Sub micro grain, with both toughness and wear resistance, suitable for making various hard alloy integral tools. Strong versatility, suitable for processing materials such as steel, cast iron, stainless steel, heat-resistant steel, nickel based and titanium alloys. With good comprehensive performance and stability, it is the first choice of integral alloy tool materials such as:Fried Dough Twists drills and end mills. |

|

FK30U |

K20-K30 |

91.8 |

14.40 |

3800 |

Sub micro grain size with good wear resistance.It has a very wide range of uses.Suitable for milling,drilling,and even processing of stainless steel and high temperature resistanct steel,chromium nickel cobalt titanium alloy steel,synthetic materials,non-ferrous materials,alloy steel,etc. |

|

FK30S |

K20-K30 |

92.8 |

14.35 |

4000 |

Ultra micro grain size,suitable for making various hole processing tools,used for processing hard cast iron,heat-resistant alloy steel,non-ferrous metals,various plastic materials,carbon fiber and other non-metals;It is also an excellent substrate for making coated cutting tools. |

|

FK40S |

K30-K40 |

92.5 |

14.15 |

4200 |

Ultra micro grain size with good wear resistance and toughness,especially suitable for making high speed milling drill bits and mold manufacturing.Suitable for low alloy steel,high alloy steel,titanium alloy,austenitic stainless steel,heat resistant alloy,glass fiber reinforced plastic,etc |

Advantage

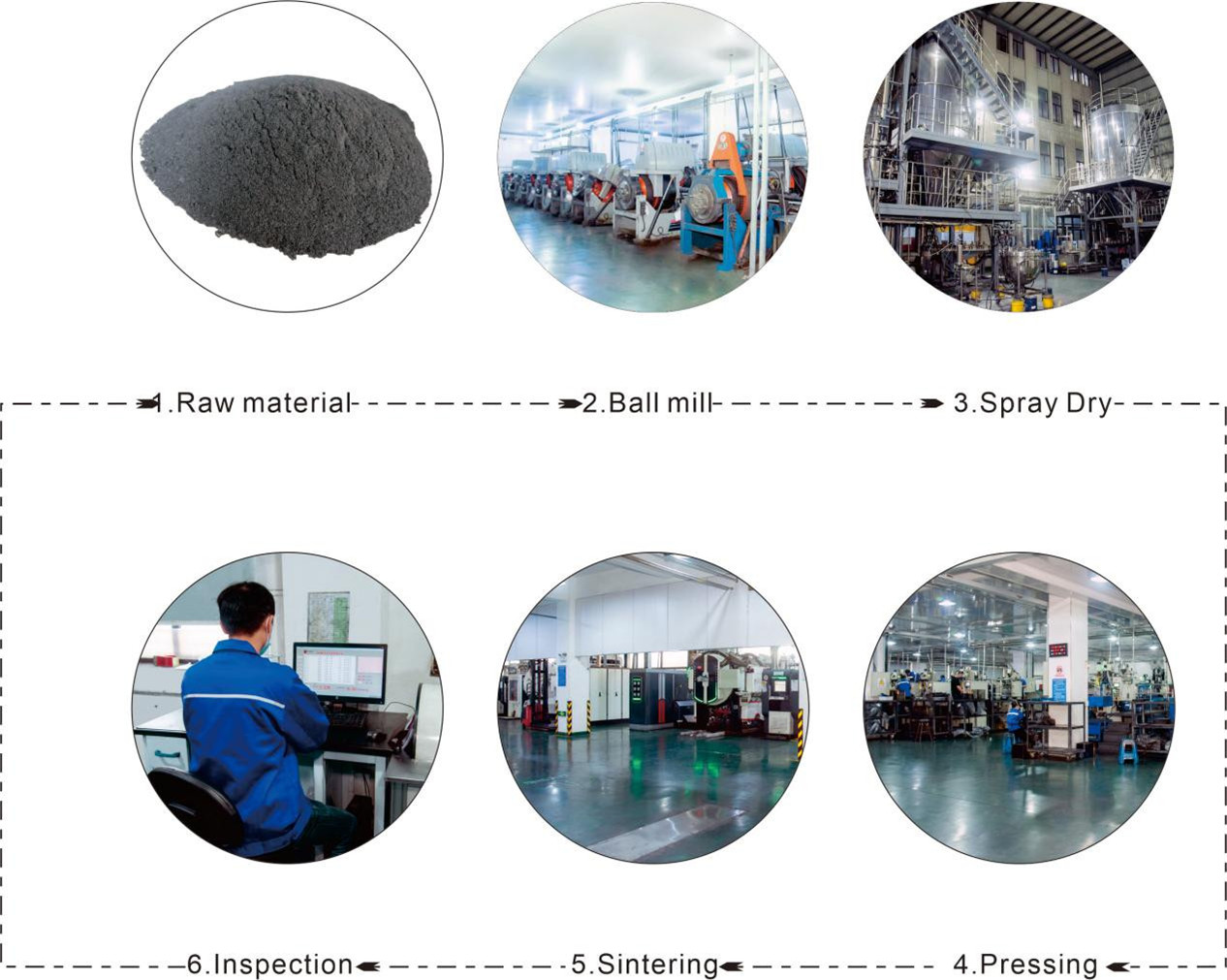

1.Our raw material control is extremely strict, from the selection of suppliers to the incoming inspection of raw materials, every step is carefully monitored by professional personnel.

2.Strict quality control is our unchanging belief. Through precise measurement, analysis, and judgment, we nip quality hazards in the bud and provide customers with excellent quality products.

3.We constantly innovate in technology, work together with excellent partners to overcome technical difficulties and promote industry progress.

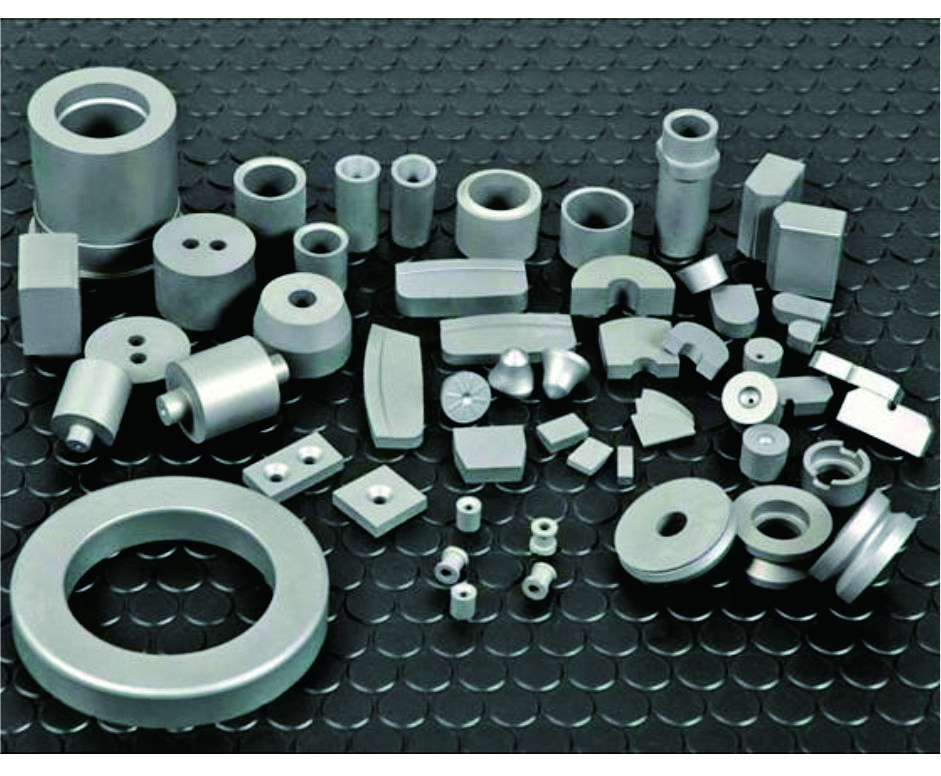

4.We closely follow the needs of our customers and continuously expand our diverse and customized fields, covering multiple industries, to provide you with an unprecedented industrial customization experience.

5.With advanced equipment and a professional team, we are able to achieve diversified surface treatments, giving your products higher added value.

6.After the new production line was put into use, our monthly production capacity broke through the bottleneck and reached 50 tons, providing strong support for expanding into a broader market.

7.We regularly conduct employee training to improve their skills and work efficiency, and reduce production costs caused by improper operations.

Process

Solution

Why choose us

We use destructive testing methods to conduct a certain degree of damage to the product in order to obtain accurate information on its internal structure and performance.

We have invested a large amount of funds to introduce automation technology to improve production processes, reduce manual intervention, and improve production accuracy and speed.

With years of industry experience and profound technological accumulation, our suppliers are able to meet the diverse needs of customers, as well as provide efficient delivery capabilities and high-quality after-sales support.

We have gained strength due to our proximity to Shanghai Port and Ningbo Port. The convenient transportation and complete logistics facilities at the ports provide strong support and guarantee for our product exports.