0102030405

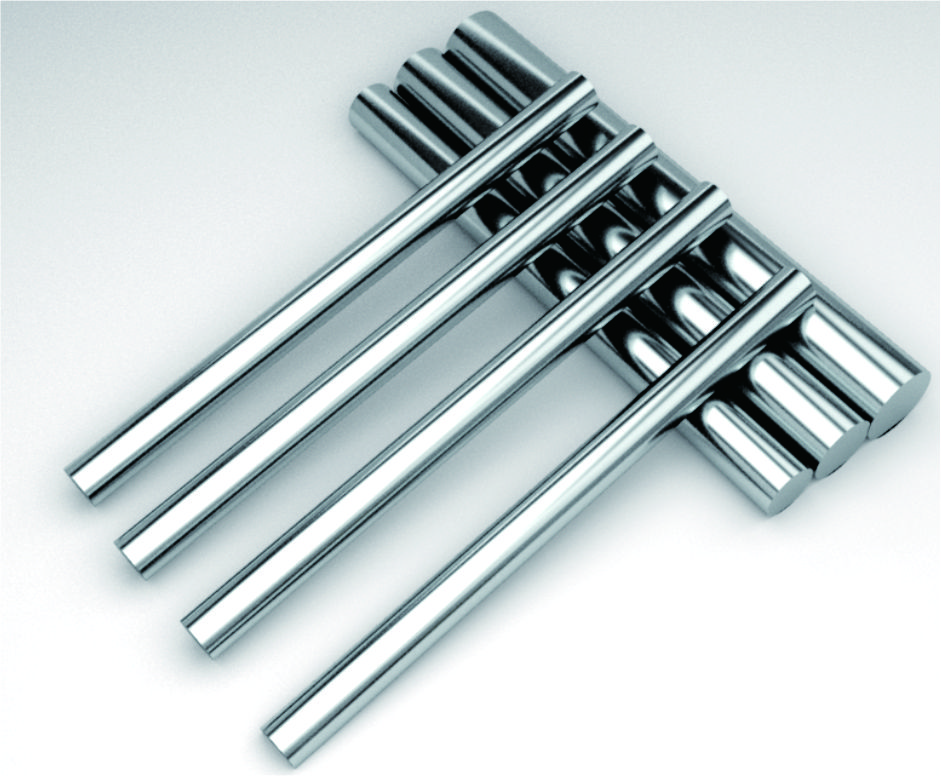

Inch-Cut-To-Length Rod For End Mill

product description

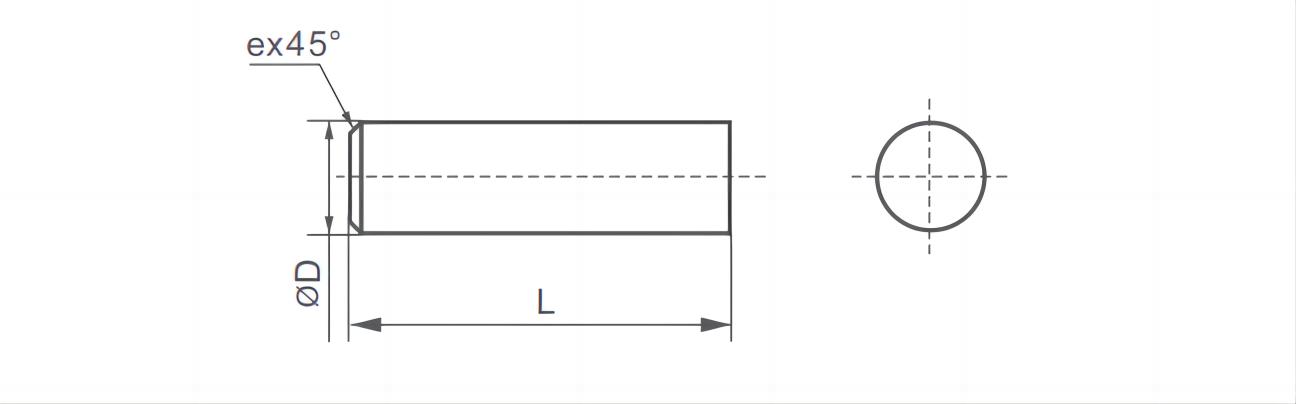

Chamfered cut-to-length ground Cemented carbide rods for end mill and solid twist drill bit

specification

| ΦD | Length | Chamfer | Angle | |

| inch | Sintered (0~+1) | (+/-0.1) | (+/-3。) | |

| 1/8 | 1-1/2,2,2-1/2,3 | 0.015+/-0.004 | 45。 | |

| 1/4 | 2,2-1/2,3,4 | 0.015+/-0.004 | 45。 | |

| 3/8 | 2-1/2,3 | 0.015+/-0.004 | 45。 | |

| 1/2 | 2-1/2,3,4 | 0.031+/-0.008 | 45。 | |

| 3/4 | 4,5 | 0.031+/-0.008 | 45。 | |

| 1 | 4 | 0.031+/-0.008 | 45。 | |

Material Property

| Carbide Grade\Property\Application | |||||

| GB Grade | I S O Grade | HRA≥ | (g/cm³)≥ | (N/mm2)≥ | Application |

|

YG6X-H |

K05 |

93.2 |

14.88 |

3100 |

Suitable for precision machining and semi precision machining of cast iron and metal, it is an excellent material for making integral cemented carbide hole machining tools. Also suitable for woodworking router bit. |

|

FD10 |

K20-K30 |

91.2 |

14.38 |

3000 |

Fine grain, suitable for various milling cutters and hole processing tool. |

|

FK30 |

K20-K30 |

91.6 |

14.45 |

3500 |

Sub micro grain size,with both toughness and wear resistance,suitable for making various tungsten carbide integral tools.Strong versatility,suitable for processing materials such as steel,cast iron,stainless steel,heat-resistant steel,nickel based and titanium alloys.With good comprehensive performance and stability,it is the first choice of integral alloy tool materials,such as:Fried Dough Twists drills and end mills. |

|

FK30U |

K20-K30 |

91.8 |

14.40 |

3800 |

Sub micro grain size with good wear resistance.It has a very wide range of uses.Suitable for milling,drilling,and even processing of stainless steel and high temperature resistanct steel,chromium nickel cobalt titanium alloy steel,synthetic materials,non-ferrous materials,alloy steel,etc. |

|

FK30S |

K20-K30 |

92.8 |

14.35 |

4000 |

Ultra micro grain size,suitable for making various hole processing tools,used for processing hard cast iron,heat-resistant alloy steel,non-ferrous metals,various plastic materials,carbon fiber and other non-metals;It is also an excellent substrate for making coated cutting tools. |

|

FK40S |

K30-K40 |

92.5 |

14.15 |

4200 |

Ultra micro grain size with good wear resistance and toughness,especially suitable for making high speed milling drill bits and mold manufacturing.Suitable for low alloy steel,high alloy steel,titanium alloy,austenitic stainless steel,heat resistant alloy,glass fiber reinforced plastic,etc |

Advantage

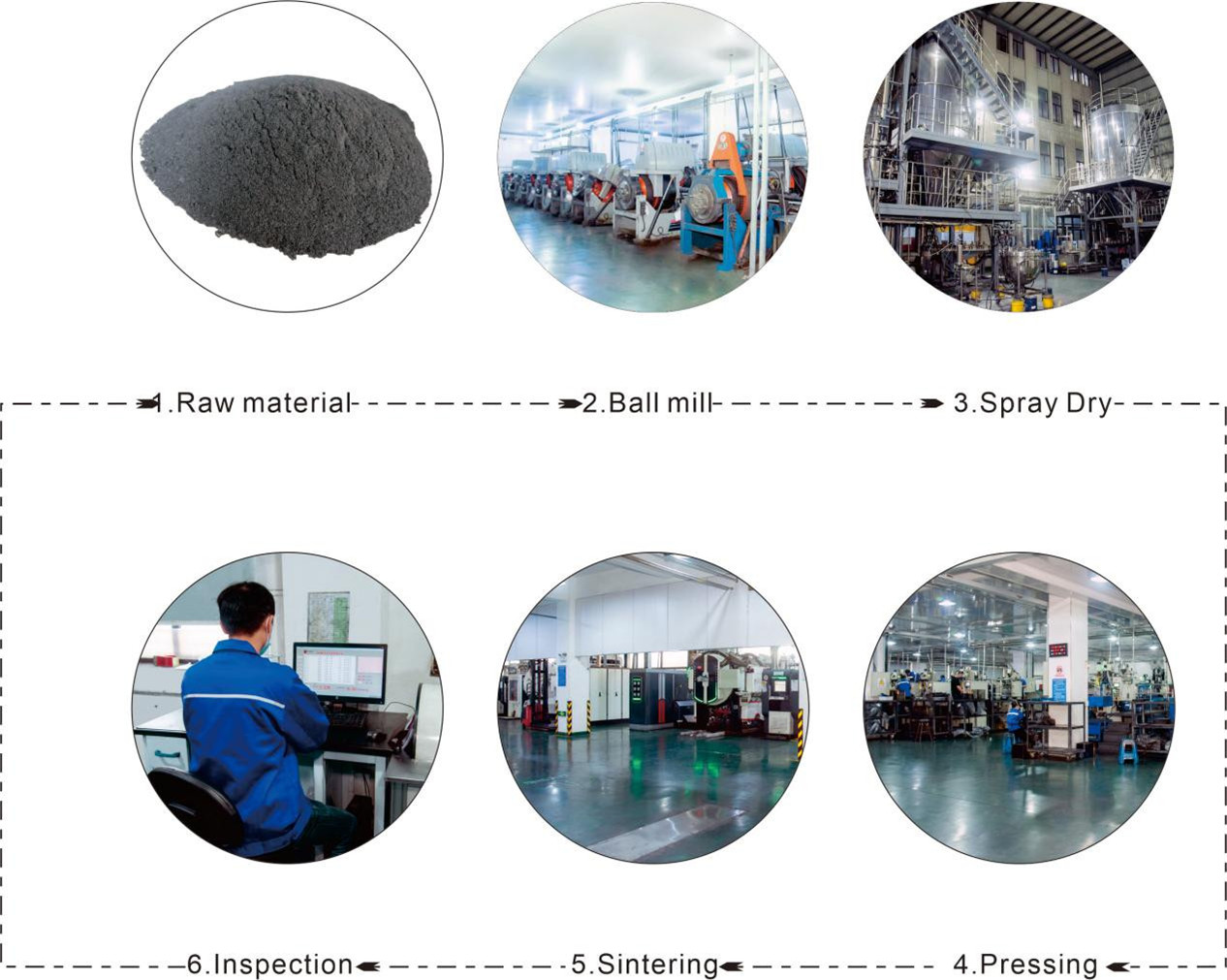

1.Our raw material control pays attention to details, not only strict requirements for the main components, but also never careless with auxiliary materials and additives.

2.With a meticulous spirit and zero tolerance principle, we strictly control product quality in all aspects and at multiple levels, making high quality our eternal commitment.

3.We have an experienced technical team that is well-known in the industry. With years of practical experience, they have provided solid technical support for the smooth progress of the project.

4.We constantly engage in technological innovation while paying attention to the protection of intellectual property rights, and transform innovative achievements into practical economic and social benefits.

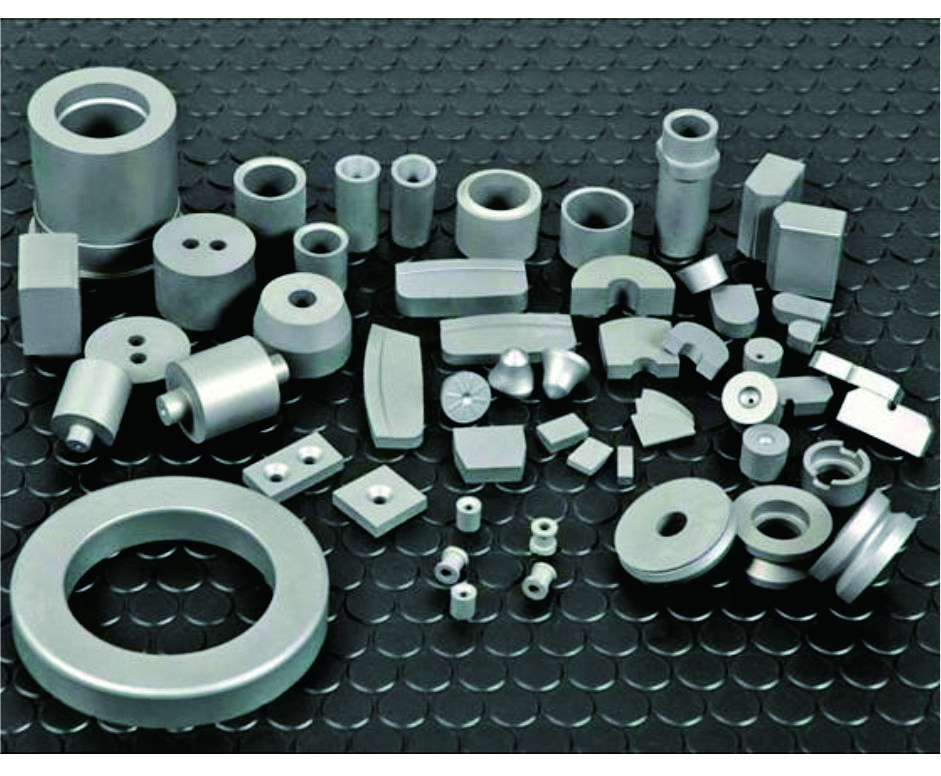

5.Customization of diversity is not only reflected in the appearance and function of the product, but also delves into every detail of the service, tailoring the most thoughtful solution for you.

6.Continuous innovation and investment have kept our monthly production capacity at a high level of 50 tons, providing customers with stable and sufficient product supply.

7.We improve production quality while reducing the production cost per unit product by introducing advanced production technology and equipment. For example, adopting automated production lines reduces manual errors and scrap rates.

Process

Why choose us

We use sampling testing to select a certain number of samples from a large number of products for testing, in order to evaluate the overall product quality.

To ensure the consistency and stability of the product, we standardize the production process by establishing unified operating procedures and quality standards.

Our suppliers stand out in fierce market competition due to their strong financial strength, extensive resource channels, and exquisite craftsmanship, becoming the preferred partners for many well-known enterprises.

Being close to the port is a unique advantage for our export enterprises. It is like a strong bridge connecting us with the global market, allowing us to gain an advantage in fierce international competition.