0102030405

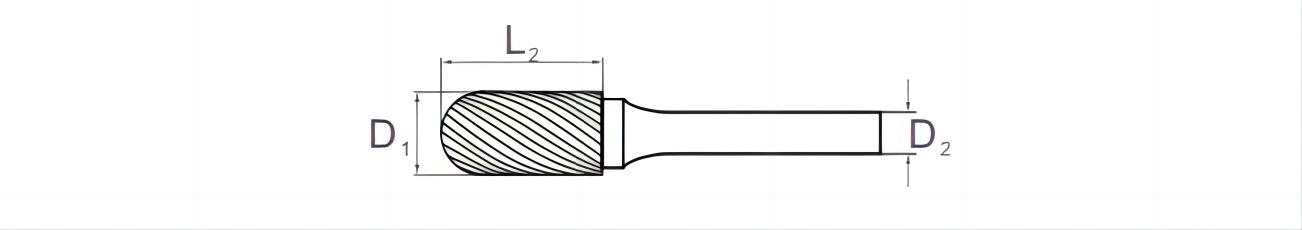

Ball Nose Cylinder Shape(BSC) For Contouring

product description

BSC Type Carbide burr(Ball Nose Cylinder Shape) for contouring, deburring

specification

Below are part of the specs, please turn to download page for the catalog to check out more specs, in metric and inch.

| Tool No. | D1 | L2 | D2 | Tool No. | D1 | L2 | D2 | |

| SC-41 | 3/32 | 7/16 | 1/8 | SC-3 | 3/8 | 3/4 | 1/4 | |

| SC-42 | 1/8 | 9/16 | 1/8 | SC-4 | 7/16 | 1 | 1/4 | |

| SC-52 | 5/32 | 1/2 | 1/8 | SC-5 | 1/2 | 1 | 1/4 | |

| SC-1 | 1/4 | 5/8 | 1/4 | SC-6 | 5/8 | 1 | 1/4 | |

| SC-2 | 5/16 | 3/4 | 1/4 | SC-7 | 3/4 | 1 | 1/4 |

Advantage

1.The series is is complete, covering different blade diameters, lengths, and tooth numbers, which can meet the diverse needs of multiple industries from woodworking to metal processing.

2.The carbide head of the burr is produced by ourselves, 100% pure and original. From the selection of raw materials to fine processing technology, every step is strictly controlled to ensure its purity and quality.

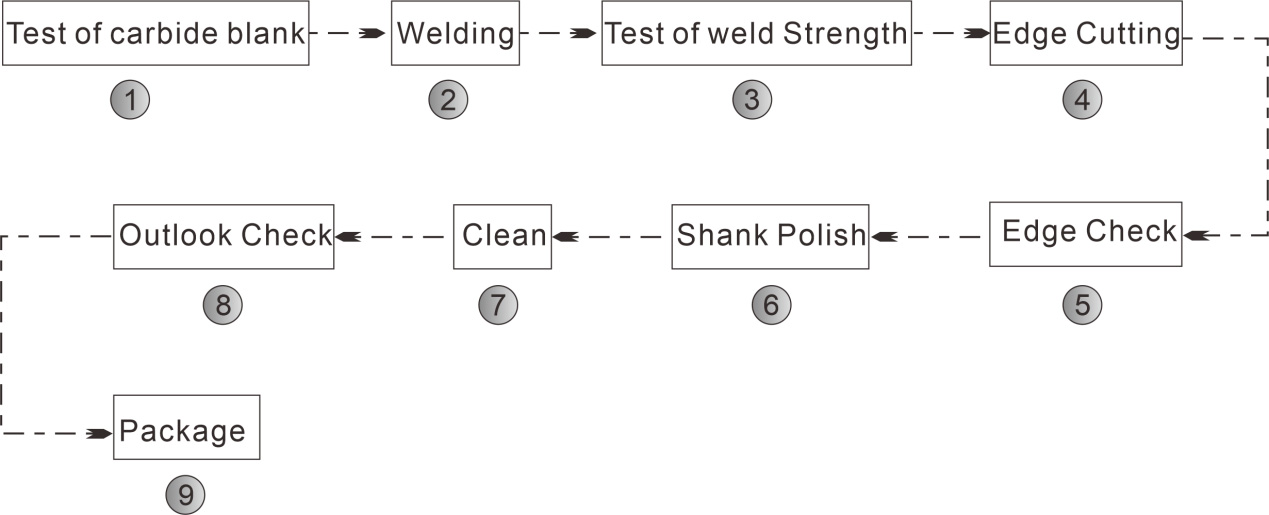

3.The testing uses advanced equipment and scientific methods to rigorously inspect each batch of products, without overlooking any potential defects.

4.Our rotary burrs have excellent quality and are designed with full consideration of user needs and practical application scenarios, known for their high precision and durability.

5.Our rotary burr quality is meticulously controlled, and advanced testing equipment and technology are introduced to comprehensively inspect the size, hardness, and accuracy of each rotary burr.

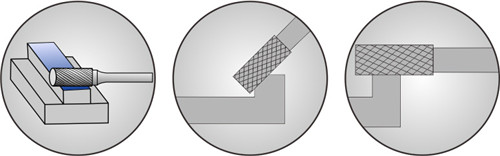

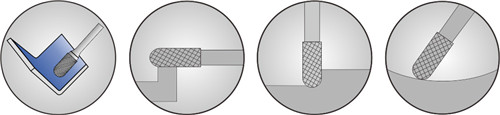

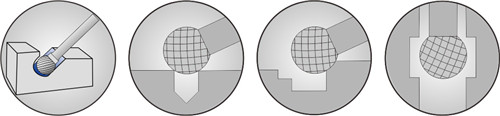

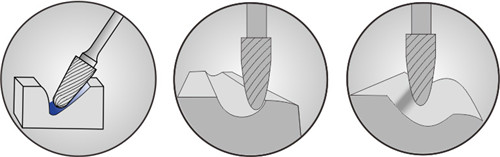

Process

Solution

| P/N | Application | Example |

| BSA | DEBURRING |  |

| BSC | Interior contour work, peripheral and face milling |  |

| BSD | Contouring,Deburring |  |

| BSE | Contouring |  |

| BSF | Interior contour work, peripheral and face milling |  |

| BSG | Work on narrow contours, milling of acute-angled surfaces |  |

| BSH | Work on narrow contours |  |

| BSJ | Machining of acute angled areas, counter-sinking. beveling/chamfering at defined angles |  |

| BSK | Machining of acute angled areas,counter-sinking. beveling/chamfering at defined angles |  |

| BSL | Work on narrow contours and surfaces, surface machining |  |

| BSM | Work on narrow contours and surfaces, surface machining |  |

| BSN | Edge machining from the rear in hard to reach areas |  |